Due to the alternative vehicle dimensions, mechanics cannot effectively or safely utilize traditional auto lifts to service heavy-duty vehicles, including buses, semi-trucks, or trailers. Fortunately, multiple manufacturers designed a solution fit for larger vehicles and introduced the auto bus lift.

Are you wondering why or when one should use a bus lift? In the content below, we discuss the purpose of a heavy-duty bus lift, address when an auto bus lift is required, and explore three common types of auto bus lifts.

What Is the Purpose of a Heavy-Duty Bus Lift?

When dealing with any automotive vehicle, it is paramount to ensure proper use of vehicle lifts. Furthermore, it is unsafe to hoist a vehicle too large or too heavy for a standard auto lift.

Therefore, heavy-duty truck and bus lifts possess extraordinary quality and enhanced durability, complete with secure locking system. As a standard to heavy-duty regulations, most bus and truck lifts can hoist nearly 70,000 lbs.

When Is an Auto Bus Lift Required?

Essentially, your operation must utilize an auto bus lift when any heavy-duty vehicle needs servicing, maintenance, or cleaning tasks completed. To adhere to safety regulations within your auto shop, any non-standard vehicle (sedan, sports car, pickup truck, SUV, or minivan) requires a special auto lift that ensures a safe environment for you and your staff.

Therefore, whether you occasionally service a bus or complete maintenance on an entire fleet of trucks and buses, you must work with a heavy-duty auto lift.

Types of Bus Lifts

Before purchasing any type of car lift, it is imperative that you consider every aspect of both your current shop’s condition and what vehicles you intend to service. Assess your lift needs by answering the following questions:

- What is your required load capacity? To safely operate any lift, we recommend purchasing a lift that exceeds your load capacity.

- Do you have a specific lift height needed? Whether you need to raise a vehicle high for your mechanics or your shop has low ceilings, take the lift height into serious consideration.

- How quickly would you like the lift to raise and lower the vehicle? While seemingly unimportant, consider how many times your mechanics raise and lower vehicles each day. Any opportunities to save time could generate a more productive workday.

- How much power is required to hoist a vehicle? Determine how much psi your hydraulic system would need to supply to operate your lift effectively and safely.

Once you determine the need for a bus lift, you can then refine your selections based on your preferred model. Below, we discuss three common heavy-duty lift types that support multiple truck and bus vehicles.

#1. In Ground – Front and Rear Bus Lifts

In-ground auto bus lifts, also known as power post lifting systems, prove extremely durable. With countless applications spanning from fire departments and municipal garages to airports and utility companies, these in-ground front and rear bus lifts range in heavy-duty lifting capacities. Below are two great models that cater to different weight classes.

2P-105-M

- Lifting capacity: 24,000 lbs., 12,000lbs front and 12,000lbs rear

- Single moveable front and single stationary rear

- Axle engaging with modified narrow range rear saddle

- Adjustable front cylinder for various wheelbase lengths

- Air/hydraulic oil or Citgo “Aquamarine” oil operated

- Post diameters: 10-5/8” front and rear

- Displacement: 50 gallons

- Lift height: 67” front and 69-3/4” rear based on standard adapters

- Multiple lip seal design for increased performance

4P-106-IB

- Lifting capacity at 250psi: 72,000lbs., 36,000 front and 36,000 rear

- Lifting capacity at 350psi: 100,000lbs., 50,000 front and 50,000 rear

- Axle engaging front saddle and adapters. I-Beam style rear superstructure equipped with adjustable saddles and adapters to engage vehicle axles, suspension, or cross frame member

- Adjustable front cylinder for various wheelbase lengths

- Electric/hydraulic oil or Citgo “Aquamarine” oil operated

- Post diameters: (2) 10-5/8” front and (2) 10-5/8” rear

- Lift height: 67” front and 69-3/4” rear based on standard adapters

- Multiple lip seal design for increased performance

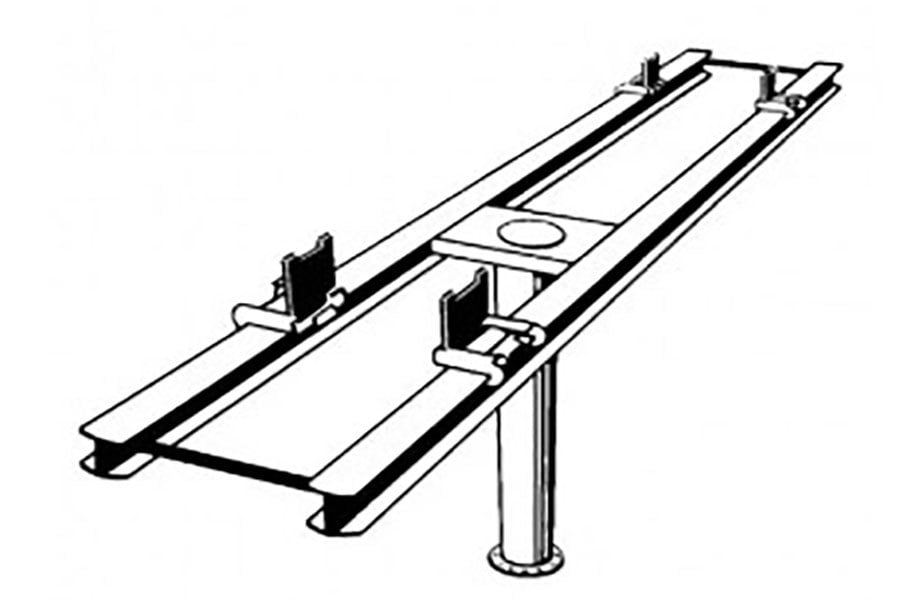

#2. In Ground – Single Post Bus Lifts

Single Post bus lifts are “multi-duty” free wheel lifts that offer an extra lifting capacity for passenger cars and light trucks. Therefore, your shop can efficiently operate on smaller buses and trucks in compliance with the below lift models and weight capacities.

LR-10

- Cylinder Diameter: 10-5/8”

- Center Load Capacity at 175psi: 12,000lbs., 6,000 front and 6,000 rear

- Superstructure: 6” rails and 216” long

- Lifting Height: 65”

- Rail Length: 17’

LR-12

- Cylinder Diameter: 10-5/8”

- Center Load Capacity at 175psi: 15,000lbs., 7,500 front and 7,500 rear

- Superstructure: 6” rails and 216” long

- Lifting Height: 65”

- Rail Length: 20’

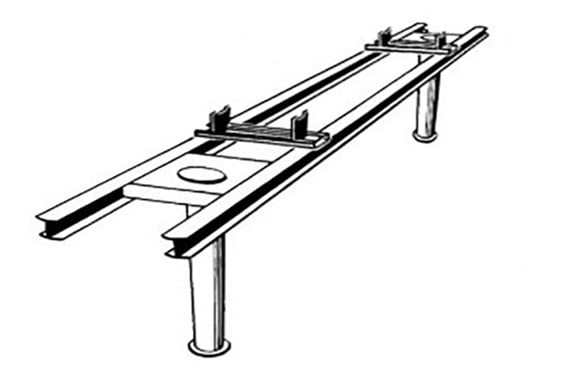

#3. In Ground – Two-Post Bus Lifts

As another free wheel, recessed rail style lift, two post bus lifts offer twin connecting rails that accommodate all cars and trucks. As a result, your shop can utilize this lift type to service any vehicle type. Below are two popular two-post bus lift models that effectively cater to multiple bus, truck, and heavy-duty vehicle dimensions.

CR-210

- Cylinder Diameter: (2) 10-5/8”

- Center Load Capacity at 175psi: 24,000lbs., 12,000 front and 12,000 rear

- Superstructure: 6” rails and 288” long

- Lifting Height: 65”

- Rail Length: 24’

CR-212

- Cylinder Diameter: (2) 12-5/8”

- Center Load Capacity at 175psi: 30,000lbs., 15,000 front and 15,000 rear

- Superstructure: 8” rails and 360” long

- Lifting Height: 65”

- Rail Length: 30’

Find the Right Lifting Application at SVI International

Whether you are searching for a specific replacement part or are looking to find the best lifting solution for your auto shop, we are here to help. SVI International is the industry leader in automotive lifts and lift repair parts.

We provide over 40,000 repair parts for a plethora of lifts and brand-new auto lifts of extraordinary quality. SVI provides innovative solutions to solve industry challenges. If in need of a discontinued part, our expert mechanical engineers will design a cost-effective alternative solution for you.

Are you interested in learning more about our products or ready to request a quote? Contact us today at (800) 321-8173 or by submitting our online contact form.