Your air compressor is one of the most valuable tools at your shop, so it’s imperative to take care of it to keep it running successfully. One of the most important ways to care for your new air compressor is by regularly changing your air filters.

Like in any machine, an air compressor filter can protect your air compressor from dust, particles, water, and possible pollutants. In addition, it keeps your compressor running effectively and helps to provide a contaminant-free environment.

Our guide will help you determine the best air compressor filter to keep your shop running smoothly!

What Are The Different Types of Air Compressor Filters?

If you are still determining what filter to purchase for your air compressor, the manufacturer will have recommendations for which filter to use and a timeline for replacing the filter. First, however, it’s essential to understand the different types of filters to make the best choice. For example, some shops may benefit from using two filters simultaneously.

Coalescing Filters

Water can easily damage your air compressor and is often the most challenging to filter. However, coalescing filters can remove aerosols, water, and oil, collecting in a moisture trap. Then you can quickly and easily empty the collected liquids. A coalescing filter can be used by itself or in conjunction with other filters, like a vapor or charcoal filter.

This type of filter can reduce liquids to 0.01 ppm and particulates to 0.1 microns, preventing contaminants from re-entering into the air compressor. It’s essential, however, to change the filter regularly, or the pressure may drop from trapped particles.

Compressor Intake Filters

A compressor intake filter is the first step in filtration, removing dust and particles entering the compressor from the outside air. This filter cleans the outside air before entering the air compressor, improving airflow and reducing wear and tear on your components. In addition, some compressor intake filters have a silencer, reducing the filtration process’s noise.

Vapor/Charcoal Filters

Vapor filters use an activated carbon bed to clear contaminants from the outside air. This activated carbon can remove chemicals, gases, and vapors that enter the air compressor, but the filter is not designed for liquids. These adsorption filters work best with a coalescing filter that first removes dry particulates and oil mists.

Vapor filters are designed to remove gaseous lubricants that the coalescing filter misses.

High Particulate Filters

A high particulate filter is recommended for body shops or mechanics who do a lot of body and paintwork. These filters remove tiny particles like metal pieces, dust, dirt, and pollen, allowing your air compressor to work effectively.

High particulate filters are very common and are easy to remove and replace when necessary.

What Filter Do I Need for My Air Compressor?

A high-quality air filter for your air compressor is imperative to avoid damage to your compressor’s components and extend the life of your equipment. The following factors will help you determine the best air filter for your shop’s needs.

Environment

Depending on your shop’s environment, you may deal with dirt, dust, water vapor, and other particulates and contaminants. For example, using an oil-lubricated rotary screw compressor or reciprocating compressor will likely produce more pollutants than a centrifugal air compressor.

Many shops will do fine with a high particulate filter, while others will add a coalescing filter.

Operating Temperatures

While most air compressors function optimally at 50-85 degrees, some can operate at a higher temperature. However, maintaining a temperature of 85 degrees or less will help your compressor run at peak efficiency.

If your shop is in an area of the country where temperatures regularly get up to 100 degrees or more, consider an air compressor with an oversized cooler option, allowing it to run in temps up to 115 degrees! Or, you can always use compressed air dryers to help your compressor avoid overheating.

However, cooler air is better overall for your compressor, as it’s usually drier and has less moisture than warm air. With dry air, you’ll have less condensation inside your air compressor and pipes and less moisture that needs to be removed by your filtration system.

Particle Size

When shopping for your compressed air filter, you might see various measurements like microns, PSE, and MERV ratings. For example, a micron (one-millionth of a meter) must be 5 microns to see it with the naked eye.

The PSE tells you the ability of the filter to remove particles at specific micron sizes. So, it’s essential to know how efficiently your filter captures microns. For example, standard filters may remove particles from 5 to 40 microns, while specialized filters can extract particles smaller than 1 micron.

The MERV rating tells you how effective the filter is at catching small particles, but it comes at the expense of the machine’s efficiency. If the MERV rating is low, it’s not as helpful in removing smaller particulates, but the filter is more efficient overall.

Pressure Drop

Another consideration when planning on which filter to purchase is the associated pressure drop. There’s a direct correlation between the filter’s air flow rate and the pressure drop, meaning that the more restrictive the filter is to airflow, the higher the pressure drop will be.

You don’t want a filter with a pressure drop higher than 5 PSI, so you’ll want to reference the pressure drop curves from the manufacturer to determine which filter is best for your needs.

When Should You Replace Air Compressor Filters?

The simple answer is that it usually depends on your air compressor’s runtime and your shop’s working environment. However, the guidelines state that inline filters should be changed after 8,000 hours or at least once a year. You’ll know if you need to replace your filter sooner if you see an excessive pressure drop.

Intake filters are usually replaced every 2,000 hours but must be changed more often if you have a dusty and dirty environment.

SVI Can Help You With All of your Air Compressor Needs

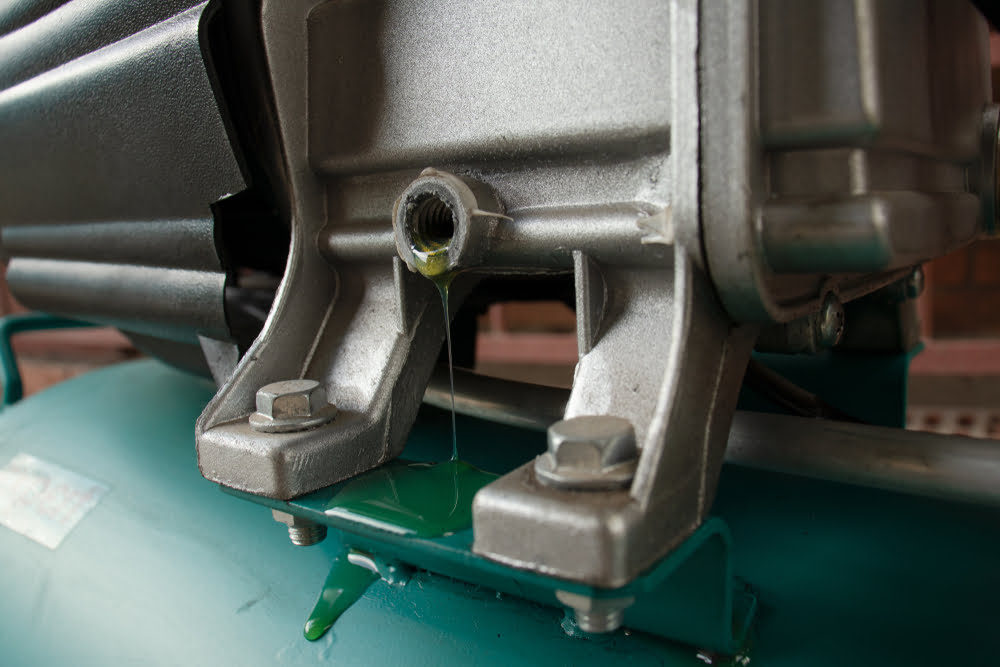

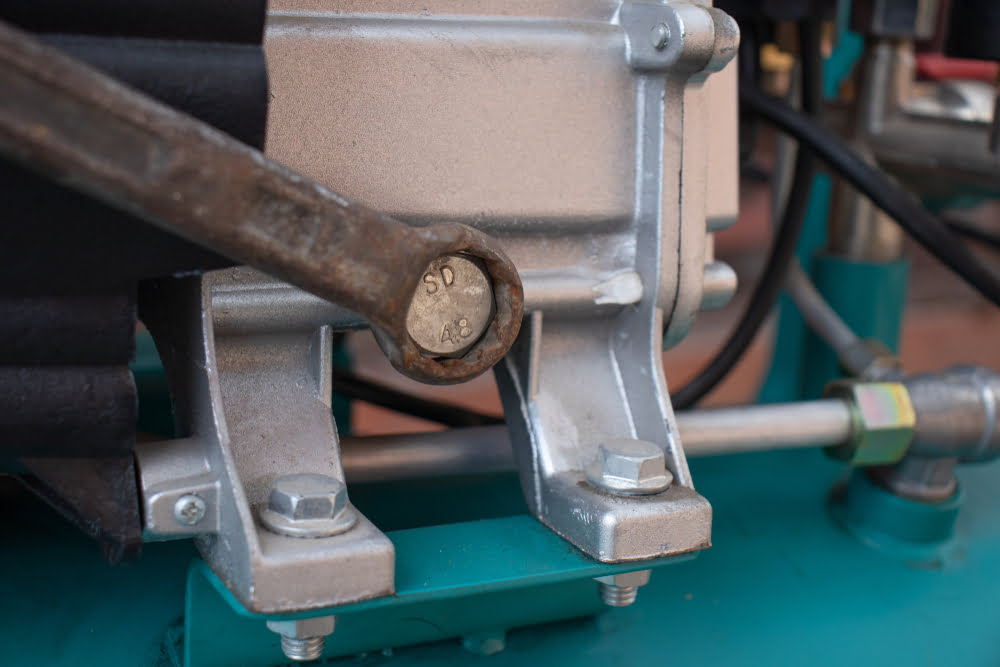

While replacing your air compressor’s filter is one of the most important ways to keep it running smoothly, unexpected repairs are sometimes required. So, whether you need a new pressure gauge, a gasket kit, or a single o-ring for your air compressor, we can help you!

Be sure to order the necessary parts before your air compressor is on the fritz- find your replacement air compressor parts now! With air compressor parts for Champion, Campbell Hausfeld, Coleman Powermate, Ingersoll Rand, Jenny/EMGLO, and more, SVI will have just what you need!

Contact us today with any questions about our air compressor repair parts- we’d love to help!