An air compressor is a valuable tool that can be used to fill gas cylinders, power pneumatic tools, fill high-pressure air tanks and tires, and more. These devices, which are made by various manufacturers and in varying types and sizes, can last for up to 28 years if properly maintained, oiled, and cleaned. Following is a comprehensive overview of everything you need to know about choosing the right air compressor oil type.

Why Does My Air Compressor Need Oil?

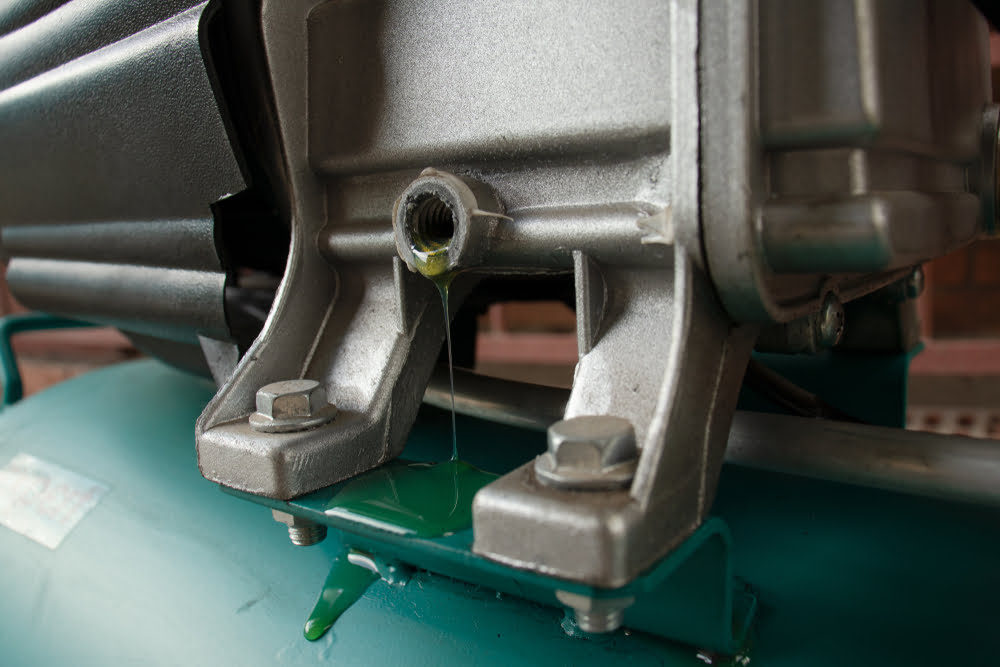

If your air compressor isn’t an oil-free model, it will need air compressor oil periodically in order to work properly. Air compressors need oil to cool and lubricate the compressor. Air compressor oil prevents overheating and acts as a sealant to prevent leaks. It also lubricates moving parts to keep the device running smoothly. You should change the oil for an air compressor every 500 to 1,000 hours of run time.

Standard vs Synthetic Air Compressor Oil

There are two main types of oil for an air compressor. These are standard oil and synthetic oil. You can use either type of oil unless the manufacturer has indicated otherwise. Both types of oil need to be stored in a sealed container in a cool, dry location to prevent spoilage. If standard or synthetic oil spills when you change your compressor oil, you’ll want to clean up the spill right away to prevent damage to your garage flooring.

Even so, there are some important differences between standard and synthetic oil. Understanding the pros and cons of each type, and when and how to use them, will help you keep your air compressor in good working order long-term.

Standard / Mineral Oil

Standard oil, also known as mineral oil, costs less than synthetic oil. Thus, many businesses that use air compressors use this type of oil to keep operating costs low. However, it’s important to bear in mind that it’s not suitable for all environments. If your shop is located in an area that gets very hot in the summer or cold in the winter, this oil won’t perform well. What’s more, air compressors that use standard oil need more frequent oil changes than compressors that use synthetic oil. Even so, standard oil offers enough lubrication and protection to keep your air compressor running smoothly for as long as necessary.

Synthetic Oil

Synthetic lubricants aren’t as flammable as standard ones. What’s more, they perform well even in extreme temperatures. They’re energy efficient and their high resistance to oxidation decreases the number of oil changes the air compressor will need. If you want to keep your air compressor in optimal shape and be able to run it continually without stopping to maintain it, synthetic oil is your best bet. It costs more than standard oil, but it’s an investment well worth making if you’re able to do so.

Substitutes for Air Compressor Oil

Air compressor oil is always the best option for your air compressor. However, if you’re in a pinch, you can use either hydraulic oil or automatic transmission fluid (ATF). However, these won’t work well for all compressors and may only work under certain circumstances. Hydraulic oil, for instance, has a high viscosity. You can use it for your air compressor when temperatures are low, but you may want to avoid doing so on a hot summer day. Not all automatic transmission fluids are compatible with all air compressor types. This means you’ll need to study the specs on the bottle before using an ATF for your compressor.

What Happens if I Use the Wrong Oil?

Using the wrong type of oil will decrease the lifespan of your air compressor. Automotive engine oil, for instance, has detergents and additives that can put a strain on your air compressor air pump. Some alternative oils have detergents that create foam in the pump and wear out your air compressor. If the oil isn’t viscous enough, your air compressor won’t run as it should.

Do All Air Compressors Require Oil?

Some air compressors can be lubricated without oil. These are called oil-free air compressors. However, they’re not typically used in professional settings. If your air compressor isn’t labeled as being oil-free, the odds are it needs oil.

Timeline for Air Compressor Maintenance Needs

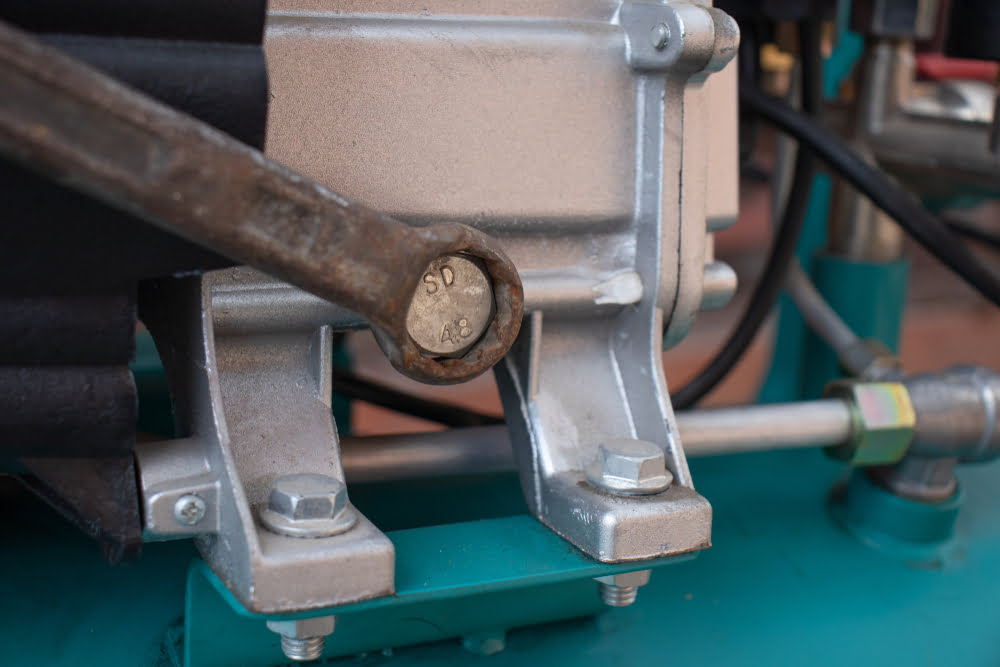

Check your air compressor for leaks every single day. You’ll also want to tighten electrical connectors and inspect hoses daily. Drain liquid accumulated in the tank using a waste oil strainer to prevent spills. Clean external components and check your air filters and oil levels every single week.

You’ll need to change the oil and air filters every month. You may also want to test the air compressor’s safety mechanisms and change the oil separator monthly.

The fuel tank and grease motor bearings should be checked once every three to six months, depending on the type of air compressor you use and how often you use it. Belts should be replaced at least a year, and you may need to replace hoses and connectors yearly as well.

SVI for all Your Air Compressor Part Replacement Needs

Spending time maintaining your air compressor and ensuring it has enough oil to run smoothly will lengthen the air compressor’s lifespan, saving you time and hassle long-term. However, even a high-quality air compressor that’s been properly cared for will occasionally break down and need replacement parts. Sometimes, this happens with little or no warning, especially if you’ve been using the air compressor a lot and/or have been working in extreme weather.

SVI is the ideal one-stop-shop for air compressor parts. The company offers a huge selection of parts for different air compressor models, making it easy for you to find what you’re looking for right when you need it. We have two ready-to-ship warehouses in different areas of the United States to ensure you get the parts you need as quickly as possible. Get in touch with us to find out more about what we offer or to request a free quote for one or more air compressor components.