Hydraulic Equipment Care for Car and Truck Lifts

Hydraulic lifts and equipment are essential for any mechanic’s shop, but if you don’t keep up with the recommended maintenance, you may deal with leaks and other issues that cause downtime. Thankfully, maintaining your hydraulic equipment is easy and can keep your shop up and running with little to no customer delays.

Importance of Hydraulic Equipment Care

The importance of having a preventative maintenance program for your hydraulic equipment cannot be overstated. Waiting until you have a leak or necessary repair will cost you money and valuable time. In comparison, preventative maintenance of your hydraulic lift will prevent customer delays and keep your shop running efficiently.

Each manufacturer has specific maintenance requirements for their equipment. Keep these documents handy, and make hydraulic maintenance and care a part of your routine schedule.

A solid preventative maintenance schedule for your hydraulic car lift includes:

- Keeping the system and drain lines clean of debris.

- Checking the oil cooler and reservoir.

- Examining cylinders and seals.

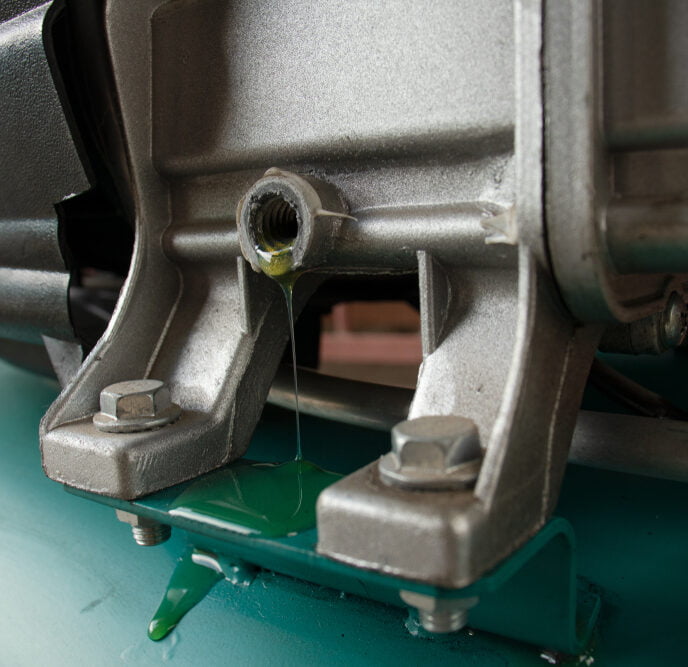

- Inspecting hydraulic hoses, tubing, and fittings for frays or leaks.

- Changing fluid filters regularly

- Investigating hydraulic fluid for color, odor, or contamination.

- Listening for loud knocking caused by cavitation in the pump.

- Checking hydraulic fluid levels and adding hydraulic fluid of the same brand and viscosity grade.

- Inspecting breather caps, filters, and fill screens.

- Examining return/pressure/hydraulic filter indicators and pressure gauges.

- Performing regular bleeding-off of air to prevent air contamination.

Common Hydraulic Lift Issues: What to Check for

If you follow preventative maintenance best practices, you probably won’t have any significant issues. However, if your hydraulic lift experiences problems, it may stem from a lack of comprehensive maintenance. These are the most common causes of hydraulic lift problems:

High Temperature

Most hydraulic equipment has hydraulic fluid that runs between 110-150 degrees, although some mobile systems run much higher.

While the hydraulic fluid is supposed to get hot when it runs through the pumps, tubing, and relief valves, if the temperature becomes too high, it can damage most seal compounds and accelerate the degradation of the oil. To prevent the hydraulic fluid from overheating, you must regularly check the oil cooler and outside the reservoir.

In addition, the high temperature can be caused by anything that increases its heat load or reduces the lift’s ability to dissipate the heat. So, it’s essential to monitor and maintain the reservoir fluid level. Also, removing any build-up of debris or dirt around the reservoir is crucial.

Lastly, any internal leak can increase the head load on the hydraulic equipment, so it’s vital to check the cylinder to see if it’s leaking past its seal or if a relief valve isn’t adjusted correctly. Once you determine the issue, you’ll need to replace any heat-generating auto lift components.

To prevent damage to your seals and increase the hydraulic fluid’s life, installing a fluid temperature alarm is a good idea.

Hydraulic Equipment Not Priming

Self-priming pumps prime themselves by drawing fluid from the tank below. While they usually function just fine, sometimes there’s a failure to prime. The most common causes of your hydraulic equipment failing to self-prime are:

- Air leak

- Debris in the impeller

- Pump is airbound

- Plugged recirculation port

- The lift is too high for the pump speed

If there’s an air leak in the suction line, the air will be drawn into the pump instead of releasing enough to create a low-pressure area.

Also, if the impeller’s eye is full of dirt and debris, the impeller can’t create an area of low pressure.

If the pump is airbound, it could mean that there is no air release line, the discharge line is pressurized, or excessive clearance exists between the wear plate and the impeller.

When the priming process works correctly, fluid is recirculated through the casing. However, if the port is clogged with debris, the impeller’s eye can’t create the low pressure needed to pull liquid up the suction line.

Lastly, ensure you have the correct size pump for the suction line, as if you’ve underestimated the pump size, it won’t be able to prime. This failure to prime is caused by the inability to create the low-pressure area it needs.

Knocking Sound When Operating the Lift

When you hear a knocking sound while operating your auto lift, it’s most likely due to air contamination. An unsuitable air balance can lead to air contamination in the hydraulic fluid. In addition, fluid vapors can implode due to the force exerted on them, also called cavitation. This implosion of air bubble vapors causes a knocking sound.

If you have air contamination, you can open the valve and bleed the air until you see the liquid coming out. However, to prevent this from happening again, it is recommended to perform regular bleeding-off of air in the hydraulic car lift. Bleeding off air opens the air valves and releases enough air until there is even circulation in the pump.

The Auto Lift Won’t Go Up or Down

Unfortunately, despite your best maintenance efforts, sometimes mechanical issues happen. Although mechanical damage is expected, you can often fix it by replacing one or more auto lift parts.

The best way to prevent mechanical issues like your lift stalling (or not moving at all) is to check all movable parts on a routine basis. Ensure the appropriate components are greased, and any worn-out parts are replaced. Preventative maintenance of your hydraulic auto lift should keep your shop running smoothly!

Hydraulic Replacement Parts from SVI

A successful auto repair shop requires automotive knowledge, the proper equipment, and an excellent preventative maintenance plan. As a dedicated mechanic, you know the importance of having a reliable and trustworthy automotive equipment parts partner. With over forty years of auto equipment experience, we have what it takes to keep your hydraulic equipment up and running. So, let SVI be your partner if you need new hydraulic equipment or a replacement part. Request a quote from us today!