Exhaust Removal Products – Technical Documents – Exhaust Blower Selection Checklist

Sizing the right blower requires knowing how much air movement is required plus the amount of static pressure. Static Pressure is the pressure in the system which is lost to friction. Ductwork, dampers, hoses and blowers all provide resistance to the air passing through them. In an air system, the common unit of pressure is the height of a water column in inches per 100 feet (wg).

Room ventilators which have no ductwork will only have the efficiency loss created by the fan and belts. There is no static pressure loss as there is no interference with the air. Ducted systems must account for static pressure loss.

Total Static Pressure is determined by adding the static pressures of any of the air handling components in a system capable of offering resistance to the flow of air. A 10 percent allowance to the sum of these static pressures is added to determine the total static pressure. Ductwork Static Pressure is calculated based on the length of the longest run of duct, the number and size of elbows, and the diameter and velocity of the largest duct and the hoses. SVI has developed handy charts to make this whole process simple. Most of the pressure loss due to friction occurs in the hoses.

Your SVI sales people can determine all these factors for you. Just give them a call.

See our Exhaust Selection Blower Checklist / Worksheet for more information about Blower Selection.

Exhaust Blower Selection Checklist

Exhaust Blower Selection Checklist Exhaust Removal Products Catalog

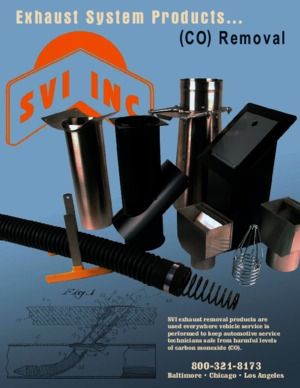

Exhaust Removal Products Catalog Exhaust Removal Products Brochure

Exhaust Removal Products Brochure SVI Line Card - Automotive Lifts & Shop Equipment

SVI Line Card - Automotive Lifts & Shop Equipment