3-5/8" Steel Cable Sheave for 2-Post Auto/Car Lifts

SVI Part #: BH-7500-50

3-5/8″ Steel Cable Sheave for 2-Post Auto Lifts/Car Lifts

A sheave (or pulley) is a grooved wheel used for holding a wire rope or cable allowing it to move freely, minimizing friction and wear on the cable. This sheave is an SVI exclusive with the strength of steel vs. nylon. This is our most popular sheave for the application and is used on various models.

Sheaves/pulleys, shafts, axles and pins should be replaced frequently to ensure proper smooth operation and extended service life of wire rope cables.

Description:

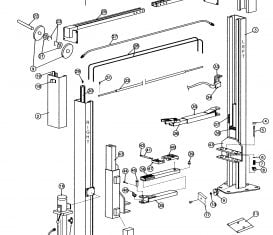

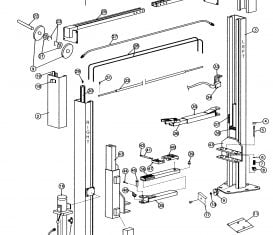

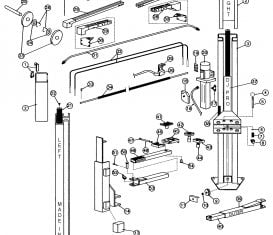

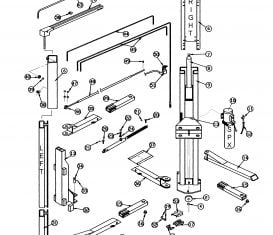

- Used on: Cables for 2-Post Lifts – various models

- Reference Number: FJ7116-1

- Outside Diameter: 3-5/8” (92.075 mm)

- Inside Diameter (includes bearing): 3/4” (19.05 mm)

- Material: Steel

In addition, SVI offers over 30,000 in-stock repair parts as well as a wide variety of cables to fit your lift. It is recommended that cables should be replaced automatically every three years or at the first sign of any wear. Always replace cables in pairs or sets and don’t forget to replace sheaves and pulleys at the same time. Auto, car, bus, vehicle, and truck lifts and hoists can be easily maintained for years of trouble-free use with SVI on your side!

SVI is a premier, well-known supplier, and your best option for replacement parts for Rotary Lifts. SVI has you covered!

Auto Lift Cables • Car Lift Cables

Truck Lift Cables • Bus Lift Cables

Safety First: Replace Auto Lift Cables at First Sign of Wear

All wire rope cables generally wear both from the inside and outside. Inside wear is much less significant and is caused as the cables are pulled across the cable pulleys or sheaves. This wear is caused by what is termed nicking and can appear on internal strands with an almost scalloped look. External wear on cables is much more apparent and is essentially abrasive wear. Abrasive wear is the result of metal being slowly worn away or removed over time. This appears on the crowns of each wire with a flattening of the wire appearance. As the wires flatten, material is being lost. Since the strength of the cable continues to lessen, the cable becomes weaker. Additionally, almost everyone at some point has seen frayed rope. This is a condition where unraveling, worn, or separated strands become evident. If this is observed to be happening on any wire rope cable assembly, immediately cease use of the equipment with this type of worn cable and replace the cable as well as the sheaves or pulleys immediately.

As a rule, if you own an auto lift or anything that uses wire rope cables, you should at a minimum conduct monthly visual inspection of the cables and sheaves or pulleys. This is especially important if your cable-driven equipment is frequently used. If you are starting to witness the small round strands comprising each cable assembly starting to flatten and then even flatter, it is time to consider replacing the affected cables. Most cables on auto lifts or even any equipment including winches are easy to replace and the costs are relatively minimal. If you do not wish to replace the cable assembly yourself, there are many companies that specialize in auto lift installation and service that can help you.

If you cannot locate an auto lift repair shop, Contact SVI and we will attempt to help you find someone in your area to properly replace your cables.

Standard and Custom cables available. In-Stock Cables or repair parts ship same-day.

SVI offers the largest selection of Auto Lift, Truck Lift, Bus Lift, Vehicle Lift, or Car Lift Cables in the industry. Contact us today!

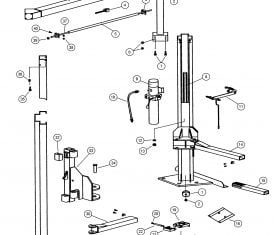

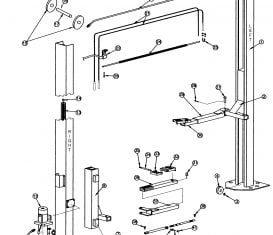

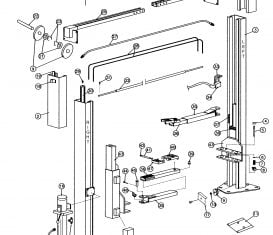

Auto Lift Parts for Rotary Lifts

Auto Lift Parts for Rotary Lifts Cable Sheave / Pulley and Chain Roller ID Guide

Cable Sheave / Pulley and Chain Roller ID Guide SVI Line Card - Automotive Lifts and Repair Parts

SVI Line Card - Automotive Lifts and Repair Parts