Lubrication Systems Types and Features

What are Lubrication Systems?

Simple machinery works well with an occasional squirt of oil. On the other hand, an engine in a complex machine needs continual lubrication to function properly. Internal combustion engines have built-in lubrication systems, but other engines use an external lubrication system. Lubricating systems continually dispense lubricant into the machinery in just the right quantities to keep an engine running smoothly.

Functions of Lubrication Systems

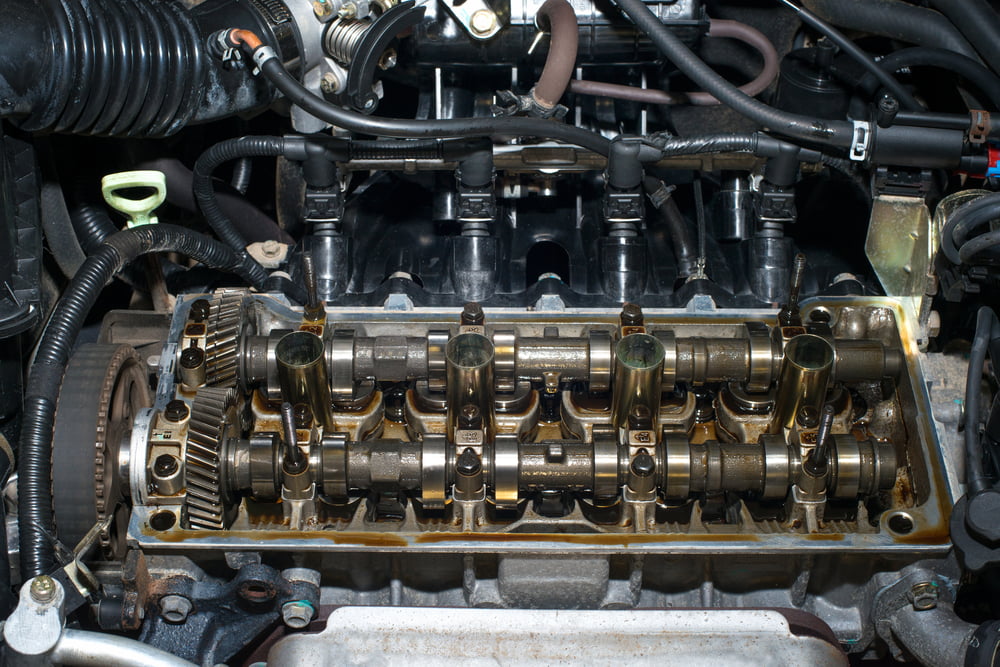

Lubricating systems vary depending on the size and type of engine. However, they all have the same basic functions. When a mechanism is turned on, the lubrication system’s pump automatically supplies oil to the crankshaft and camshaft bearings. The oil then flows through groves on the crankshaft’s main bearings, traveling to the sump, through holes in the connecting rods, and on to the piston and cylinder.

Lubricating System Components

Lubrication systems have eight main components. These are the oil sump (also known as an oil pan), oil pump, oil filter, oil strainer, oil cooler, oil level indicator, oil pressure gauge, and oil pressure indicating light.

The oil sump holds oil and covers the crankshaft. The oil pump supplies oil to parts under pressure. The oil filter removes grit and dirt particles from the oil as it circulates. The strainer stops dirt and grit from getting into the oil pump.

The oil cooler prevents the lubrication oil from overheating. This keeps viscosity levels high, so the oil can circulate through the system with ease. The indicator enables you to measure how much oil is in the lubricating system while the indicator shows if an oil change is needed.

Types of Lubrication Systems

There are five main lubrication systems used in motor vehicles. These are the petroil lubrication system, the pressure lubrication system, the semi-pressure lubrication system, the wet sump lubrication system, and the dry sump lubrication system.

Petrol Lubrication System

This is the simplest lubrication system and is typically used in motorcycles and scooters. The oil is added to the vehicle’s fuel, and it lubricates the bearing surfaces, piston rings, cylinder walls, piston pins, and other engine components when it passes through the vehicle’s crank chamber.

Pressure Lubrication System

A pressure lubrication system distributes lubricant to the engine under pressure feed. The oil moves from the sump into the pump to lubricate the main bearing. In the process, some of the oil is also splashed on the cylinder walls while the rest goes into the crank pin. From the crank pin, the oil lubricates the piston rings, timing gears, and camshaft.

Semi-Pressure Lubrication System

Much of the oil in a semi-pressure lubrication system is circulated in the same way it would be in a pressure system. However, some parts of the engine are also lubricated via the splash method. A scoop at the lowest end of the connecting rod dips into oil every time the crankshaft makes a full revolution. The oil is then splashed onto the cylinder walls.

Wet Sump Lubrication System

Wet sump oil systems are safe and don’t have many parts to repair or maintain. What’s more, the oil doesn’t have to travel far from the sump to the parts that need lubrication. When a wet sump lubrication system is running, the oil goes from the sump to lubricate different moving parts of an engine before dropping back into the sump.

Dry Sump Lubrication System

In a dry sump lubrication system, the oil is kept in a separate tank rather than the sump. Vanes sweep the oil from side to side to lubricate moving parts in the engine.

Types of Machine Lubricants

There are four types of machine lubricants: grease, oil, dry lubricants, and penetrating lubricants. Oil and grease are by far the most common. Oil is used to lubricate hinges, bearings, and sharpening blades. It’s also used for tool maintenance. It’s ideal if you need to lubricate something without taking it apart. Grease, which is thicker than oil, is used to lubricate gears, bearings, chains, and linkages. It’s the perfect lubricant if you need to seal out dust and moisture, and/or if you have a tool you need to keep lubricated even though you don’t use it very often.

Dry lubricant is typically applied with spray equipment. It’s used on locks, hinges, threaded rods, tiny parts, and surfaces exposed to high heat and/or pressure. Penetrating lubricants are used to break up rust and remove chewing gum and adhesive stickers from various surfaces.

How Much Oil or Grease to Use?

The amount of oil or grease you should use in a lubrication system depends on the system type, the type of lubricant, and how often the system is used. Check the owner’s manual to know how much and which type of lubricant to use for your lubricating systems.

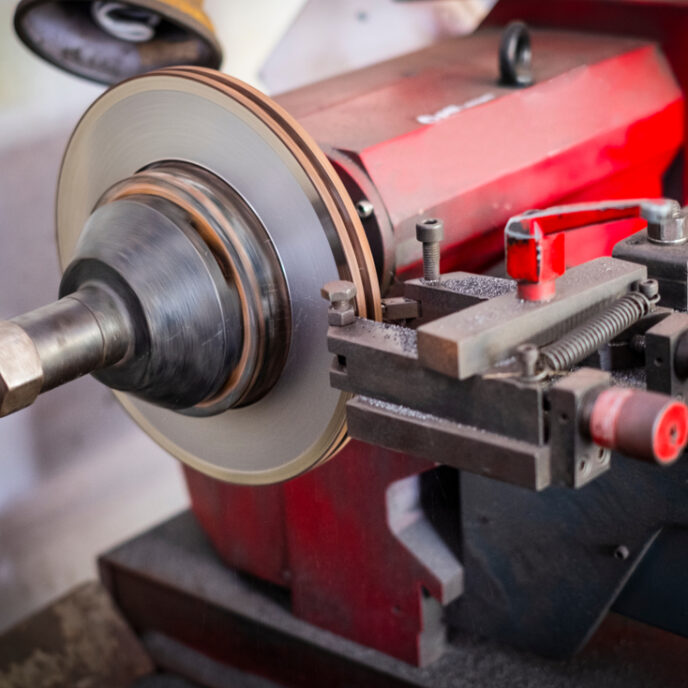

Maintenance Needs for Lubrication Equipment

Lubrication equipment needs more than lubrication. It also needs regular maintenance. The lubrication system’s strainer needs to be cleaned and emptied regularly. You’ll want to periodically check your system’s hoses for cracks and holes. The tubes and pipes should be checked for signs of breakage and the connecting points should be examined for leaks. Once a year, you’ll need to replace the suction and pressure filters and clean the screens. If the wrong lubricant is added to the lubrication system or the system hasn’t been used in some time, you will need to use a waste oil pump to remove old oil before adding new lubrication. If you need new lubrication system components, SVI offers a huge array of parts to meet any auto shop’s needs. Our two ready-ship warehouses are on standby, ready to mail your order right away to ensure you get the parts you need without undue delay. Get in touch with us to find out more about our services or inventory, or to request a free quote.