How to Use a Hydraulic Car Lift

One of the most crucial purchases you can make for your auto shop or garage is a car lift. Car lifts are used more frequently than any other piece of equipment in your shop, and therefore, you need to ensure that you’ve got a reliable and trustworthy lift.

However, choosing the perfect one might be challenging with so many brands and models on the market.

How Does a Car Lift Work?

Various applications employ hydraulic systems, including automotive braking systems, forklift trucks, presses, and pumps. Hydraulic car lifts follow the same basic idea.

The main components of a hydraulic lift are:

- a cylinder with a piston (called a ram)

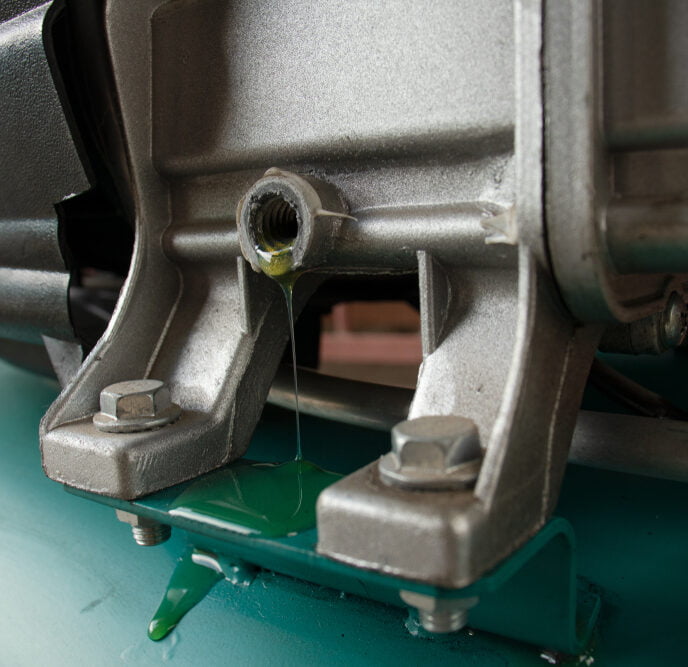

- an oil tank or reservoir

- a pump

- a motor to drive the pump

- a valve

Hydraulic lifts function by pumping oil into the cylinder and pressing the piston (which pushes the lift vehicle) higher. Then, the valve opens to allow oil to flow back into the reservoir and be pushed back by the lift car’s gravitational force as it travels down.

Choosing the Right Lift for the Job

Several types of hydraulic car lifts are on the market, but not all are applicable in every environment. Therefore, it’s essential to consider the following things when shopping for the right lift.

Check for Capacity and Clearance

It’s crucial to check the lift’s capacity, clearance, foundation requirements, and access to manufacturer-recommended lifting points. The lift’s consistency and ease of use are also things to consider.

For example, your capacity needs might let you get away with a scissor lift, but your lift height needs might necessitate a 2-post or 4-post lift.

Two-post car lifts are a style of lift that supports the weight of a vehicle with two metal arms, but you must consider lifting points. So, you must correctly determine the proper lifting points when using a two-post car lift, which can vary with each car. Because of this, two-post lifts necessitate greater caution and precision when in use.

While every automobile lift requires you to be cautious, a four-post car lift lets you drive your vehicle onto the platform without worrying about proper lifting points. There’s no guesswork ensuring your vehicle is aligned correctly when all four wheels support the vehicle’s weight.

Scissor lifts can raise the vehicle to 36 inches off the ground, so a scissor lift might be perfect if you don’t need a high lift clearance. Mid-rise scissor lifts can go up to 48 inches in height, whereas full-rise scissor lifts can go even higher. You might think that all scissor lifts are limited in capacity, yet parallelogram lifts are among the heaviest lifters available.

Verify Safety Standard Certification

The International Building Code mandates that all vehicle lifts fulfill the ANSI/ALI ALCTV safety standard. Therefore, while it is lawful to sell car lifts that do not comply with the ANSI/ALI ALCTV standard, most building codes prohibit the installation of non-compliant lifts.

Do your research and ensure that the manufacturer is not making a false claim about proper certification. You can always double check using the Automotive Lift Institute’s website in their Buyer Beware section.

Also, if you decide to add accessories to improve your lift, confirm that the supplemental items are an approved add-on for your specific lift.

How to Use a Hydraulic Jack to Lift a Car

You’re undoubtedly already familiar with the fundamentals of using a car lift. However, not all lifts are created equal. Training on how to use your lift correctly is essential for safe lifting. Before you use it, make sure you’ve been trained and are familiar with the manufacturer’s instructions, especially if it’s a new or different kind.

Step 1: Pull the Car Forward

Drive the car slowly to the lifting platform and put it in neutral. Ensure all doors are locked and that no one is inside the vehicle. Keep an eye out for antennae and overhead racks obstructing your elevation.

Step 2: Secure the Car

If you have a two-post lift, you must secure the car using the recommended lifting points. First, attach the arms to the car’s base and double check for stability by shaking the vehicle to confirm stability. Then, visually check all the lifting points again. The two-post lift can be challenging to use, and you must make sure the vehicle is adequately balanced.

If you have a four-post lift, you need to set the car on the platform and ensure that the chocks are in place, so the vehicle does not slip.

Step 3: Test the Lift

Start the lift once you are sure that it is sturdy enough to support the car’s weight. Once raised to the required height, confirm that it is placed correctly.

Always double check the chocks or locking mechanism for the vehicle’s stability atop the elevator.

Step 4: Perform Maintenance or Store Your Vehicle

You can now perform any necessary maintenance, or store your vehicle for parking purposes.

It would be best to stay at the controls throughout the lifting and lowering procedure when you’re using a lift. Never disable the controls, features, or safety mechanisms by blocking, overriding, or disabling them. What may save you a few seconds may result in a severe accident.

Step 5: Lower Your Vehicle

First, ensure there is nothing underneath the platform, and then lower the vehicle slowly until it reaches the ground. Then, unlock the locks and chocks, and the car is safe to move.

Automotive lifts are necessary pieces of equipment to have in your bay or garage. They serve a variety of purposes, the most important of which is to provide a safe and convenient area for mechanical tuning of the car.

There are numerous types of lifts on the market and you can choose the one that best suits your needs. Should you need help deciding which lift is best for you, please contact our experts at SVI International. We can help you find the perfect lift for your needs!